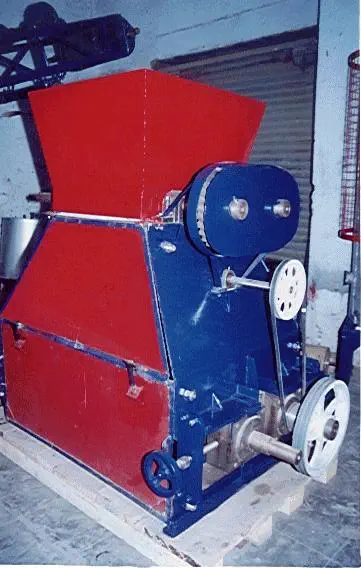

Our Crushing Mills are designed to handle the primary, secondary and tertiary stage crushing of friable materials such as Coal, Salt, Clay, Bauxite, Limestone, Oil cakes, Food Grains and other minerals of similar characteristics in the mining, power generation and numerous other industries. Our Roll Crushers are one of the most widely used crushers in such industry and have numerous advantages, such as high capacity, low headroom, low horsepower, the ability to handle wet, sticky feeds and the generation of minimum fines while producing a cubical product.

The simplified design gives these units excellent reliability and requires very little maintenance. Roll Crushers are designed with built-in tramp relief that allows the passing of uncrushable materials while continuing operation and returning to the initial product setting.

Our Crushing Mills can be used for Salt Refinery, Solvent Plants, Flour Mills and for any soft stone crushing requirements. We have various models for different applications and with different production capacity.

Our Crushing Mills are fabricated with thick MS Plate and all standard spare parts. In case of Salt Refinery processing, our Crushing Mill body is totally covered with Stainless Steel (SSL316) plates from inside wherever salt comes in contact with Crushing Mill body.

The only difference between Salt Refinery Crushing Mill & other application Crushing Mill is that it is covered from inside with SS Plates for Salt Refinery Crushing Mill whereas this is not required for other processing units likes Solvent Plant etc.

- 05 T/H to 15 T/H production capacity

- Strong body of M.S. plate - 15mm thickness

- 2 pair of Imported Chilled Cast Iron Roller

- Pre-Crusher, Size - 250mm x 500mm L

- Fine Crusher, Size - 250mm x 1000mm L

- Imported self-alignment bearings

- Bearings are covered by Pedestal with Oil Seals

- 2 sides are totally closed

- Gears, Pulley and V-belt

- Easy and very less maintenance

- Maintain Variable Speed

- Inside completely covered by 2mm S.S. plate (in case of Salt Refinery only)

- Divider between pre-crusher and fine-crusher

- Using Special Grade S.S. plate, conforming to international standard

- All nut & bolts

- Hopper

- Adjustment screws

- Side alleviation of windows

| Criteria | MCN T5 | MCN T10 | MCN T15 | MCN PT3 |

| # Rollers | 2 | 4 | 4 | 2 |

| Roller Size(L x Dia., In mm) | 1000 X 250 | 500 X 250 (2)1000 X 250 (2) | 1000 X 250 (2)1000 X 250 (2) | 500 X 250 (2) |

| Feeding Size(mm) | 15 to 20 | 15 to 20 | 15 to 20 | 15 to 20 |

| Output Size(mm) | 3 to 5 | 3 to 5 | 3 to 5 | 3 to 5 |

| Capacity(T/hr) | 5 | 10 | 15 | 3 |

| Motor Power(HP) | 15 | 20 | 25 | 5 |

| Weight(KG) | 1200 | 1800 | 2200 | 1000 |

| Dimension(L x W x H)inch | 40 x 36 x 50 | 40 x 36 x 60 | 40 x 36 x 60 | - |

Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll. Shear and compression forces occur as the feed material is pulled between the crushing rollers.

Depending on the feed size, material is fed into the crushing chamber and encounters a pair of rotating rollers. If two-stage reduction is required, either a Triple or Quad Roll configuration can be used. In this scenario, the top stage of the crusher performs the primary reduction by crushing the material between a pair of rollers. The material is then fed directly between the two bottom-stage rolls for additional processing.

If a single-stage reduction is required, then depending on the feed-to-product-size ratio of reduction, either a Single or Double Roller Crusher can be selected. Regardless of the crusher type selected, Roller Crushers allow the material to fracture along naturally occurring cleavage lines, which helps with minimizing fines generation.

- High throughput capacity

- Accepts large feed sizes while producing small product sizes

- Cubicle product with minimal fines

- A variety of roll tooth profiles available

- Proprietary & simplified designed

- Adjustable for change in product sizing

- Automatic tramp relief

- Minimal maintenance required

- Low cost per ton operation

A two roll crusher feeder mechanism specifically designed for crushing and feeding of material to feed grinding mills and reducing material to a uniform size.

We are the authorized supplier of Crushing Rollers. We supply various kind of Crushing Rollers i.e. different size and different type of rollers based on the application where it will be used.

- Roller Diameter from 10" to 24"

- Chilled Cast Iron Rollers- Grooved, Plain

The motor drives the fixed roller and movable roller to work via reducer and coupling. Materials are put into the space between the two rollers via the feed entrance.

As the two rollers turns inward, the input materials are crushed, pressed, ground, and at last come out from the base of the machine.

A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with an endless loop of carrying medium—the conveyor belt—that rotates about them. One or both of the pulleys are powered, moving the belt and the material on the belt forward. The powered pulley is called the drive pulley while the unpowered pulley is called the idler pulley.

- Heavy duty M.S. fabricated body

- Bakelite wheels to position as per requirements and convenience

- S.S. drum rollers

- Totally enclosed Pillow block bearing and Pedestal

- Three-ply rubber belt as per I.S. standard

- Folding support to change degree as per requirement

- Maintain Variable Speed

Horizontal screw conveyors are the most widely used type of screw conveyor. Used to convey bulk materials from one part of a process to another, horizontal screw conveyors are available in a wide range of sizes, lengths, configurations and materials of construction.

- Complete Rust-less SS body. Size as per your requirement

- Maintain variable speed.

Screw conveyors are typically designed to convey bulk materials at 15, 30 or 45-percent through loading, depending upon material characteristics of the specific bulk material.

As a general rule, loading of 45-percent can be used for light, free-flowing and non-abrasive bulk materials.

Loadings of 15 and 30-percent are typically used for denser, sluggish and more abrasive bulk materials.